New Infrastructure with New Plan (2): Data Center Cooling

In recent years, China's data centers have developed rapidly, and the market size has grown by over 20% annually. The construction of big data centers and 5G base stations is an important project for the upcoming "new infrastructure", which has pushed China's data center industry into a wave of vigorous development. How can we seize the opportunity for a refrigeration system that provides "escort" to the data center, accurately controls environmental temperature, and provides high stability services?

As is well known, in order to facilitate data retrieval anytime and anywhere, the data center is almost in a working state 24 hours a day, with an MTBF (Mean Time Between Failures) greater than 100000 hours. This requires stable and reliable cooling system components, with a "long" lifespan and even working with "illness". Today, Xiaohua will dismantle them one by one for everyone.

solenoid valve

The action of the solenoid valve in the system is equivalent to a continuously driving car, and the core iron and sealing plug are like tires. Not only will they wear out during long-term operation, but they are also prone to tire blowouts due to the maximum shock absorption when passing through large rocks or potholes at high speeds. The Sanhua MDF solenoid valve adopts a "soft landing" design, which is equivalent to equipped with an extremely reliable "shock absorption system", not only minimizing wear and tear, but also easily responding to abnormal working conditions.

Three flower MDF solenoid valve

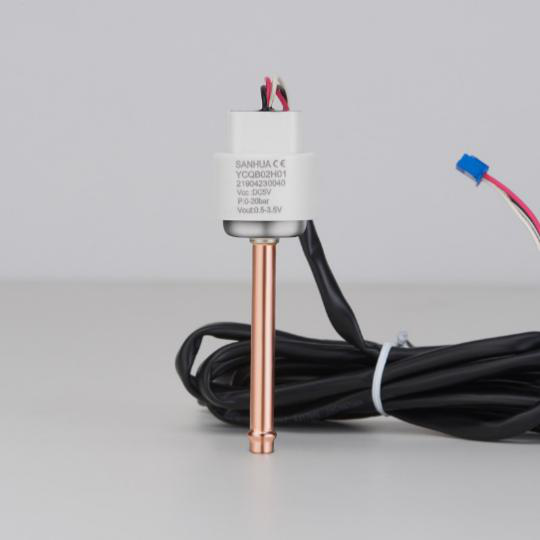

pressure transmitter

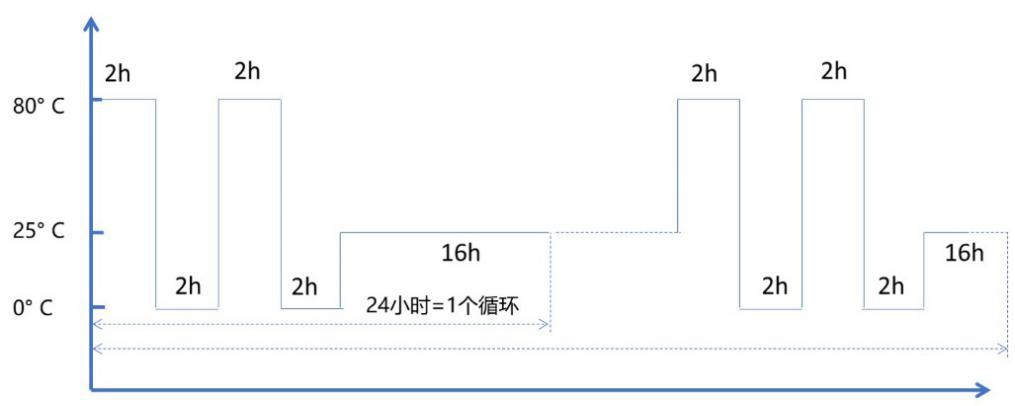

Perhaps you are concerned about accuracy, but in reality, a large part of the failures on the market are caused by poor sealing, which leads to internal circuit failures. The aging, incompatibility, or alternating cold and hot environments of the sealing ring are the main reasons. The three flower YCQ design does not require any sealing rings, and the innovative external sealing design does not give any chance of sealing failure. In the field of pressure transmitters, there is an extremely strict set of impact tests in this regard. The three flower design can easily complete more than 50 cycles, while many designs on the market fail if they cannot pass 5 cycles of testing.

Severe impact testing

The energy consumption of data centers mainly comes from IT equipment, cooling systems, lighting systems, and power systems. At present, the energy consumption of the cooling system in data centers in China accounts for about 40% of the total energy consumption of data centers, making it one of the largest sources of energy consumption in data centers. Therefore, energy-saving of the cooling system is of great significance for improving energy efficiency of the entire data center.

In terms of energy conservation, Sanhua offers a variety of solutions.

DC variable frequency control

Although the scale of data center cooling systems is sufficient to cope with peak loads in extreme situations, they mostly operate under low load conditions. The variable frequency controller improves the flexibility of the motor, allowing the cooling system to adapt to constantly changing load conditions, thus maintaining efficient operation of the system even under partial loads.

Sanhua provides DC frequency conversion technology as an energy-saving tool for data center cooling systems! Equipped with the most advanced 180 ° sine wave control technology, with a maximum power of 22HP, it can still work safely in an environment of -40 ℃. The module has multiple software and hardware protections, and the frequency converter can choose air cooling or refrigerant cooling for its own heat dissipation.

Of course, the most important thing is that the overall solution achieves energy savings of over 30%.

Although Sanhua's DC variable frequency control scheme

Application of Maglev Centrifuge

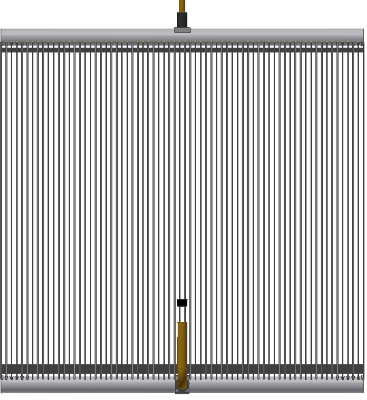

Oil free electronic expansion valve VPF

The Sanhua VPF electronic expansion valve has been widely used in large chillers, and the VPF developed for magnetic levitation centrifuges adopts a special bearing design to easily meet the challenge of oil-free lubrication.

No matter what system design you choose, Sanhua can provide reliable and efficient solutions, helping you take a step ahead in the competition of "New G Construction".